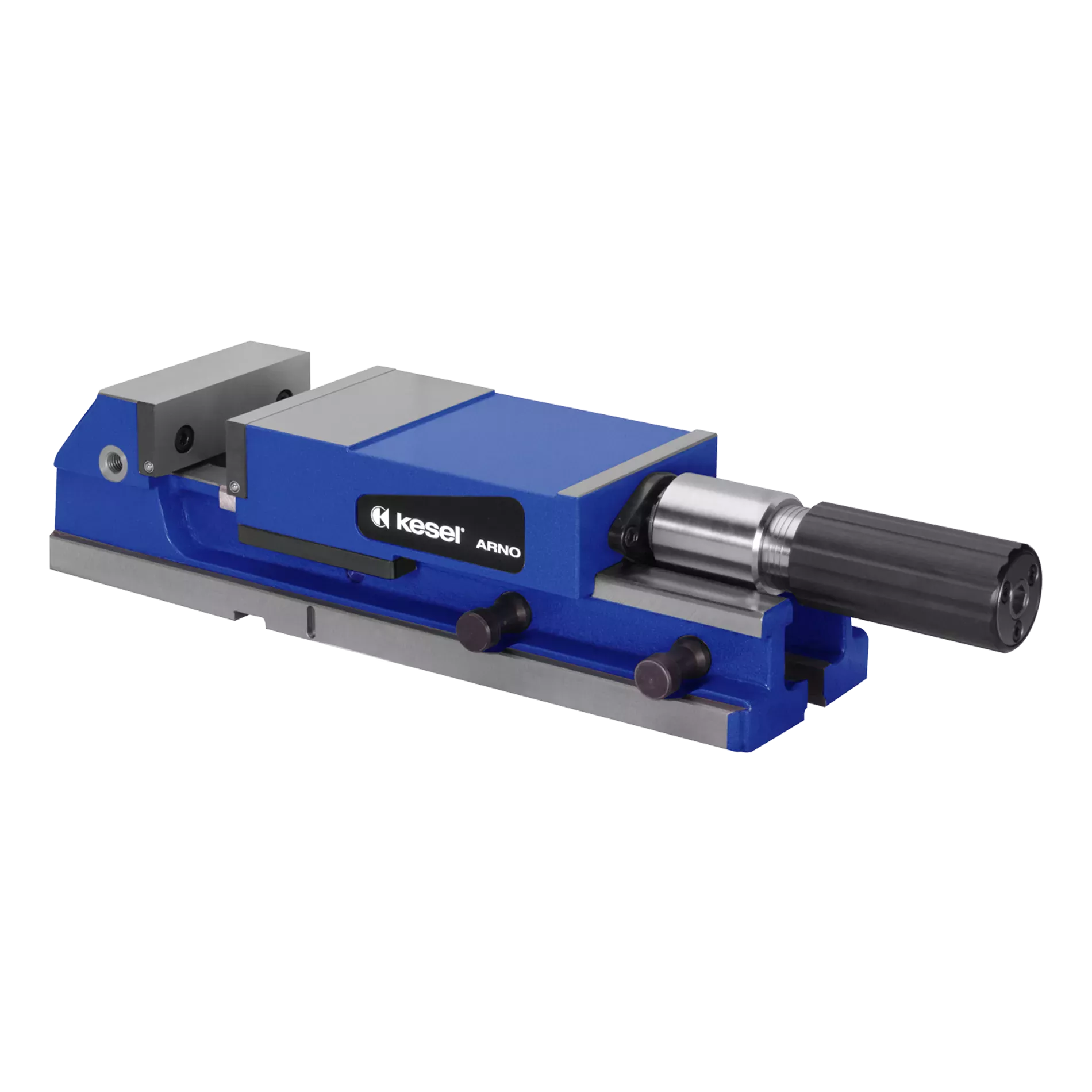

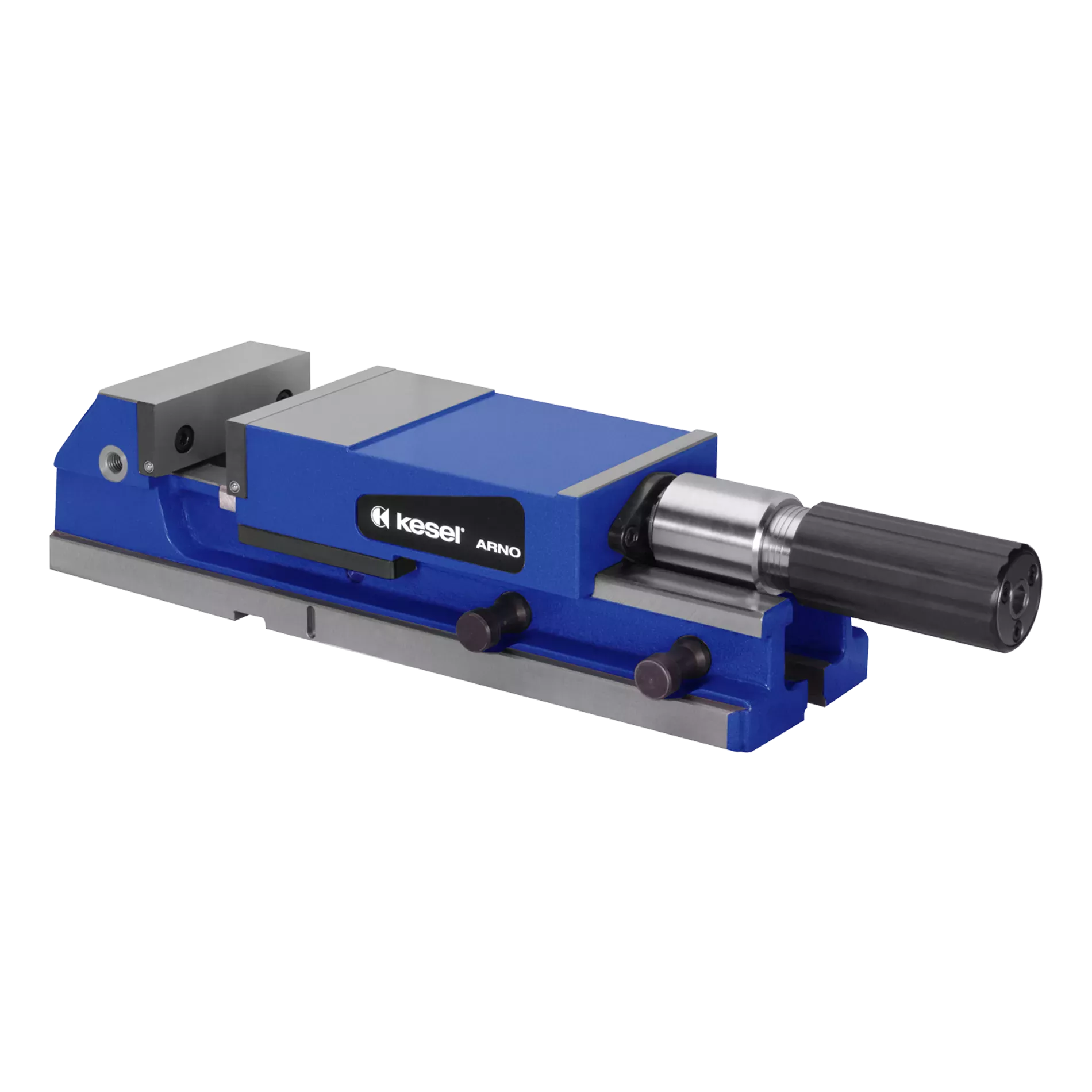

High Pressure Machine Vise

ARNO

| Jaw width: | 91 - 125 mm, 126 - 200 mm |

|---|---|

| Processing: | conventional processing |

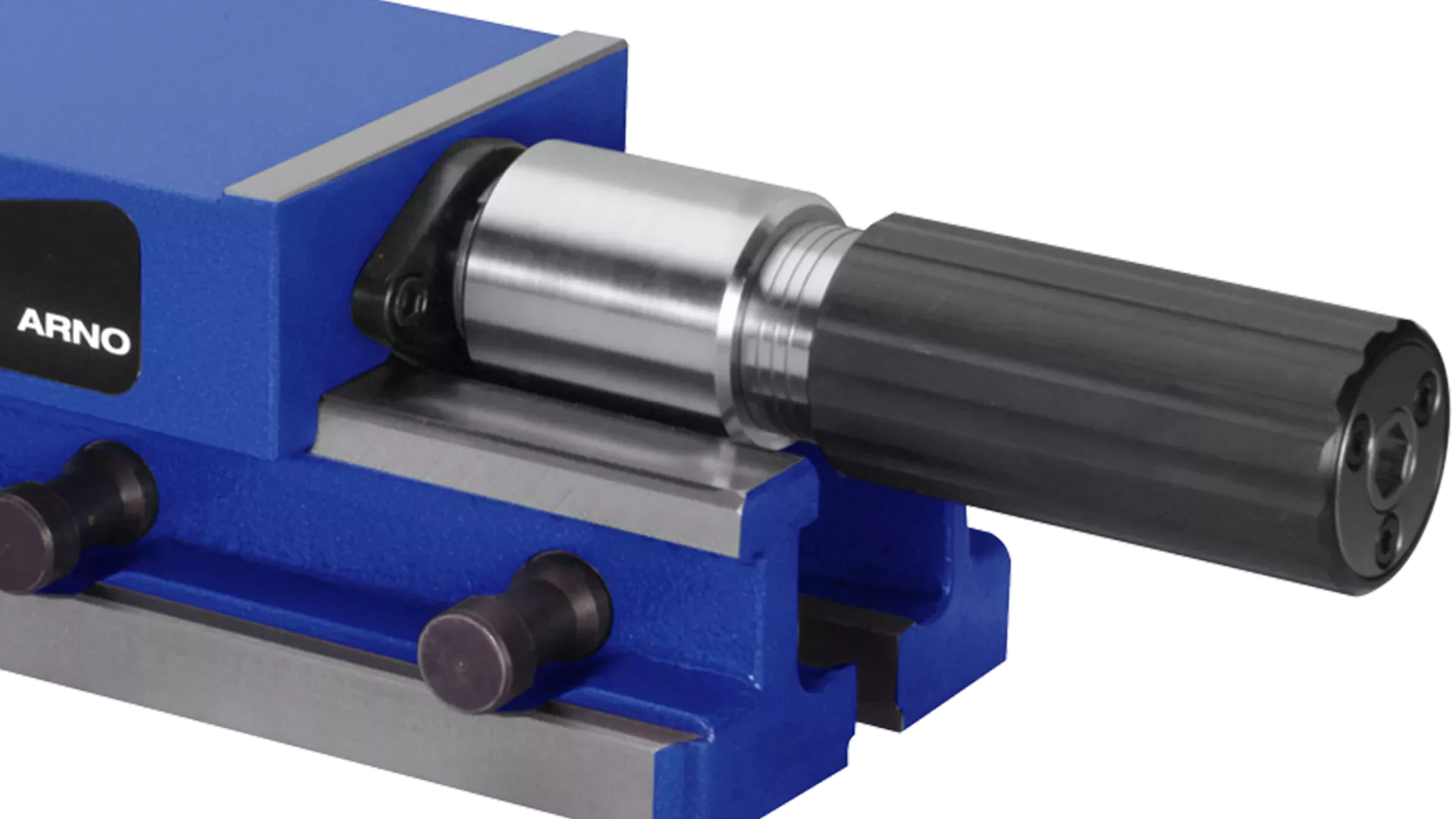

Choice between hydraulic and mechanical power booster

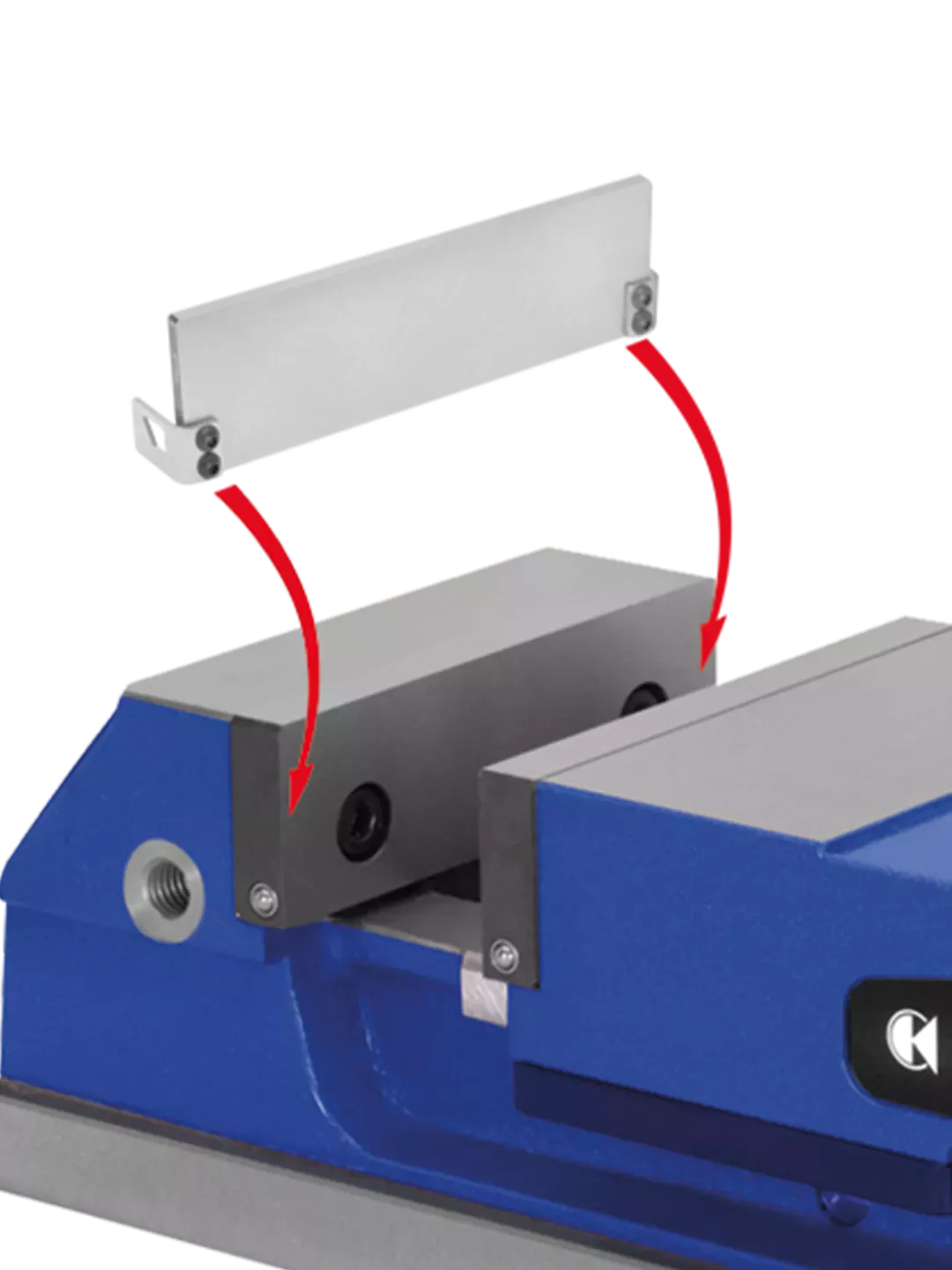

Integrated step bar quick-change system

Classic high-pressure clamp for conventional production

- Functional surfaces hardened and ground

- Optimum accuracy on the workpiece due to ground-in "camber" on the fixed jaws

- Scope of delivery: incl. 4 clamping claws, 1 crank handle

Any questions?

Contact Sales DepartmentIn Action!

360° View

FAQ

Why is the ARNO High Pressure Machine Vise available with a hydraulic or mechanical spindle?

The hydraulic spindle is smoother, with optical clamping force display and slightly a lower cost.

The mechanical spindle is more durable, with exact clamping force adjustment and pretensioning capability.

How is the "extended" clamping range set?

With the extended clamping range, the last pin is inserted through the groove of the spindle nut. This results in even more clamping range.

What does the ground-in "angle" on the fixed jaw mean?

The fixed jaw is manufactured with an acute angle of approx. 0.05 mm to the base body.

The clamping force clamps the fixed jaw to an exact angle of 90°.

The hand crank rotates without the workpiece being fully clamped.

The 3 cylinder screws on the face of the spindle should be tightened to the recommended torque.

The bearing washer with which the spindle is fixed to the upper part is broken.

This bearing washer is actually not broken, but is made of 2 parts in order to be able to mount the spindle.

My ARNO High Pressure Machine Vise is no longer stretching properly. What should I do?

If the crank handle can be turned without significant resistance during clamping, the full clamping force is not achieved, the spindle is defective. Please send the spindle to us. You will then receive a cost estimate for the repair.

Any questions. We will help you

Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect