Machine Tool Vise

Syncroline

| Jaw width: | 91 - 125 mm |

|---|---|

| Processing: | 5-Axes processing, Automation |

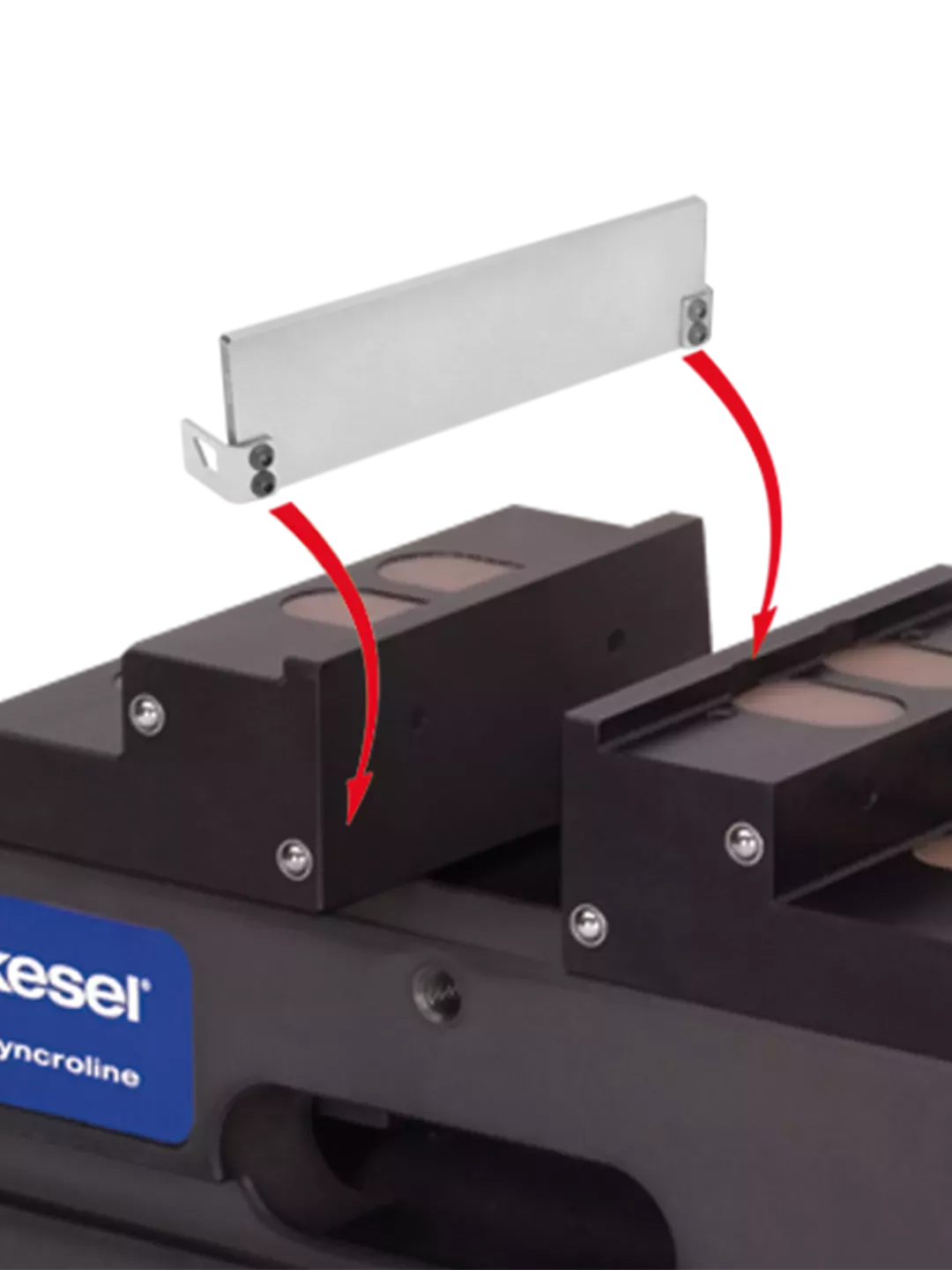

Simple conversion from central to single clamping system

Quick change jaws thanks to the patented quick-change jaw system

Integrated step bar quick-change system

- Screw-on "grip" bars

- Optimum chip protection of the high-pressure spindle due to patented wiper technology

- Alignment possible via longitudinal and transverse grooves as well as via 0-point clamping systems

- Scope of delivery: incl. 4 clamping claws

Any questions?

Contact Sales DepartmentIn Action!

FAQ

What is the advantage of a centric clamp over one with a fixed jaw?

With centric clamping, the center of the workpiece is always centered in relation to the vise, regardless of the workpiece length. This ensures optimum accessibility, centered programming and centered distribution of allowances.

How does the quick-change jaw system work on the Synocroline Machine Tool Vise?

When changing the jaws of the Syncroline Machine Tool Vise, it is not necessary to unscrew 4 screws completely, but only 2 screws by 1 turn. Then the jaw can be pulled off over the screw head and changed.

Does the Syncroline Machine Tool Vise machine vice have a clamping force adjustment?

The Syncroline Machine Tool Vise is clamped with a torque spanner. The clamping force increases linearly with the set torque.

What clamping forces can be achieved with the Syncroline Machine Tool Vise?

The maximum clamping forces are 35 kN.

How does the conversion from the centric version to the version with fixed jaws (single-version) work?

The modification is carried out by means of a conversion kit. This means that the base body and the jaws can be used for both the centric and the single version.

What are the steel ball-bearings in the jaws used for?

These are spring-loaded pressure points. Our Kesel step ledges (support ledges) can be clicked into these.

Any questions. We will help you

Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect